INDEX

1. Things which Only a Small Factory Could Achieve.

2. And Here Comes the Ambition.

3. Endress Trials.

3.Endress Trials.

Combine “Cooking” & ”Eating” into one.

Although TENT and FUJITA METAL MFG managed to set clear ambition, their journey was never easy.

On this story, we are going to talk about many twists and turns we experienced until we actually reached to production of the frying pan “JIU”.

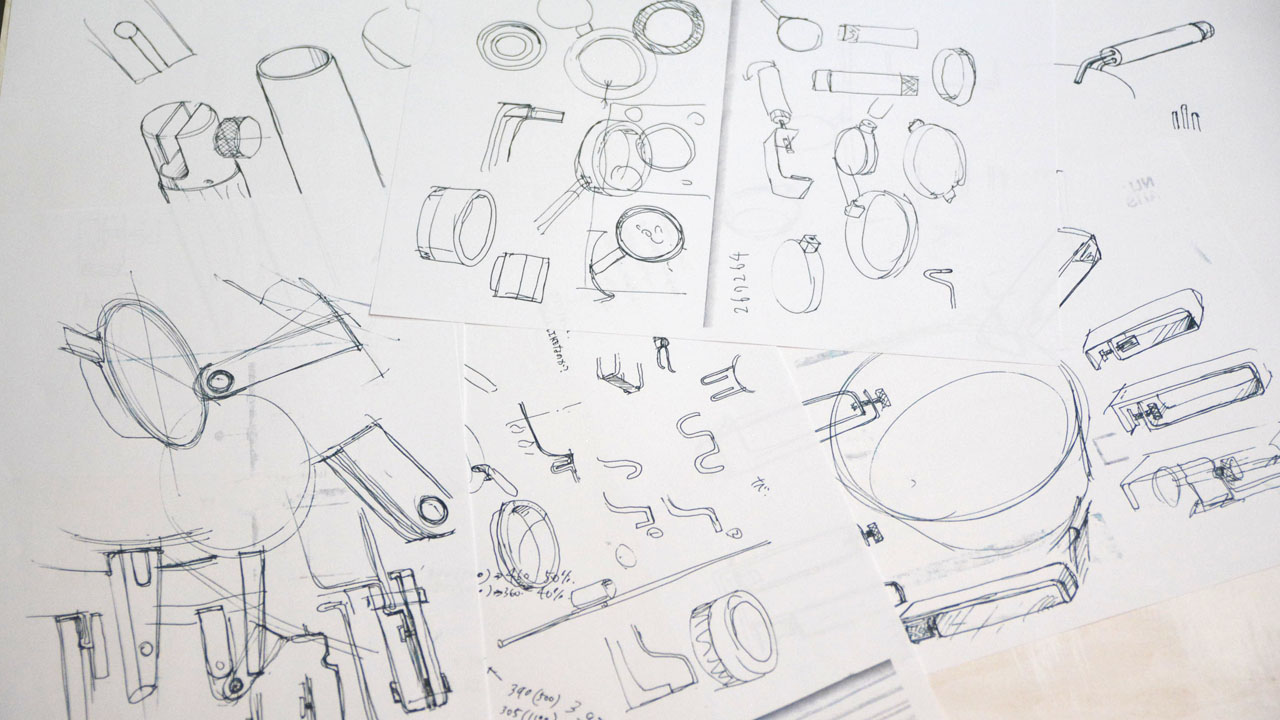

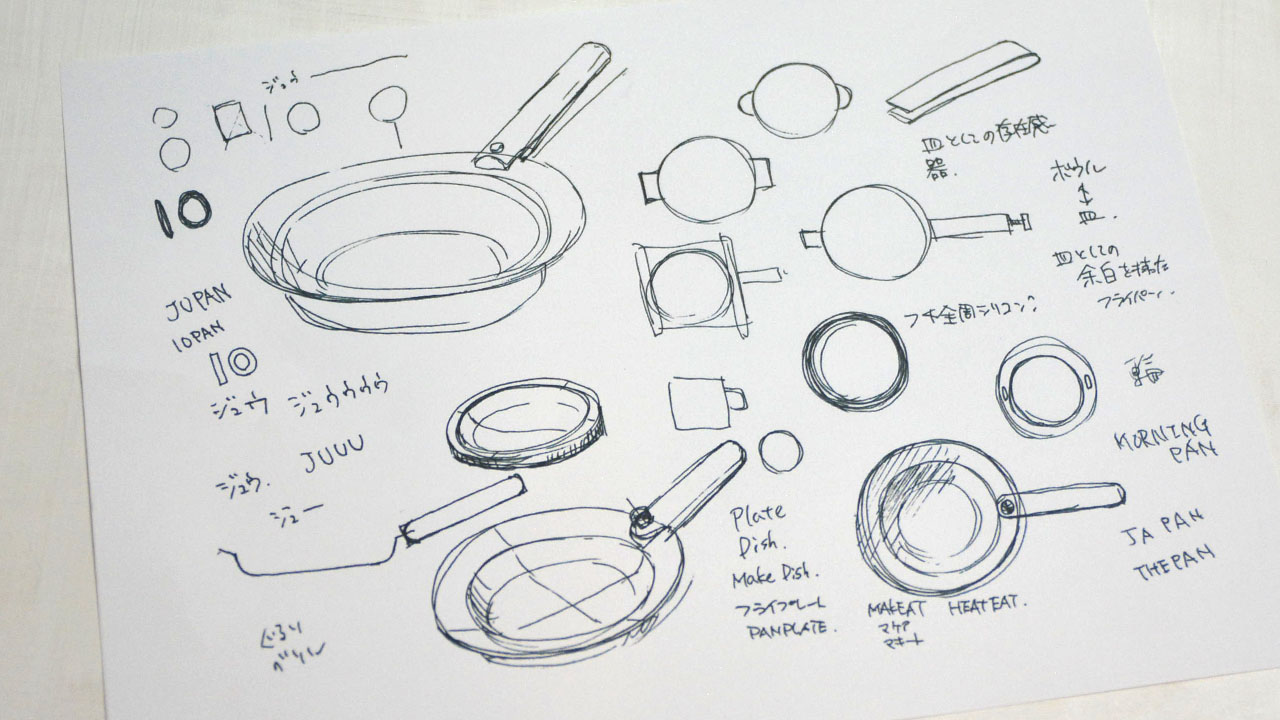

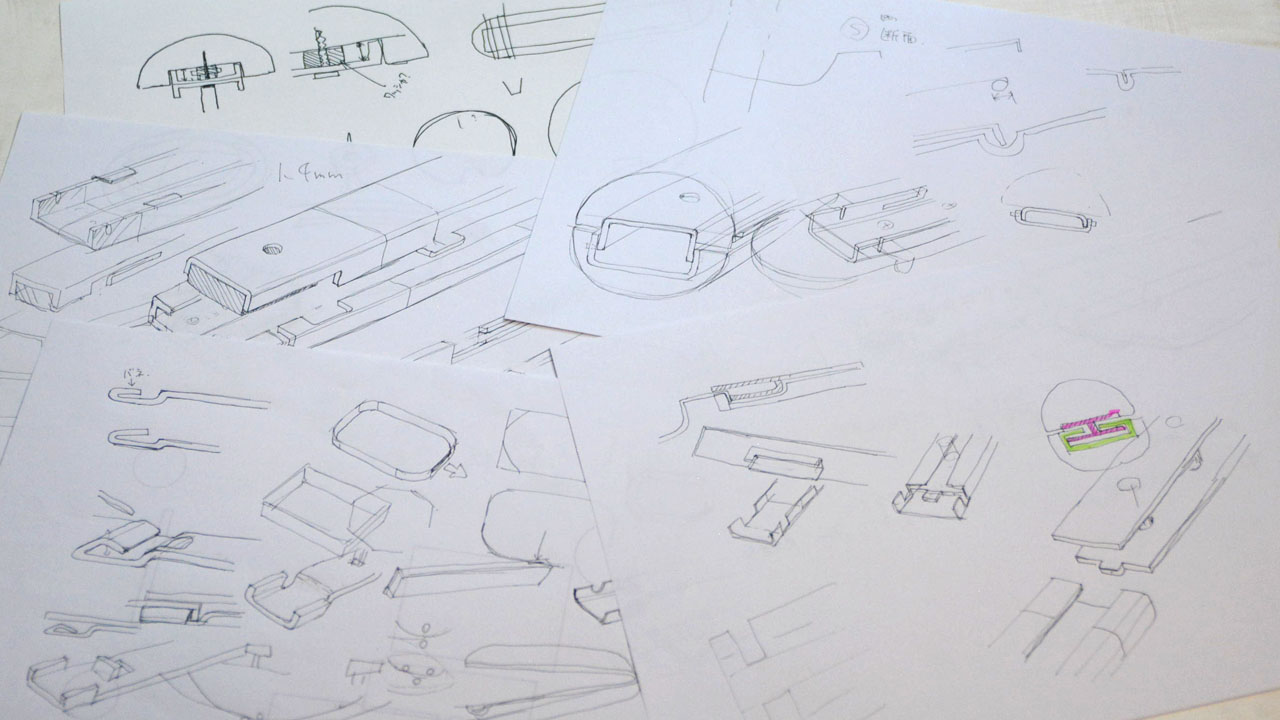

SEICHIRO @ FUJITA We had a short discussion and we have roughly decided that we want to produce a frying pan with detachable handle. I remember that after a couple of weeks, you already came back with the sketch which was pretty close to the final version of the frying pan “JIU” on the very first meeting.

AOKI @ TENT Wow, it is surprisingly close to the final version of it. But there actually were many twists and turns until we got there.

HARUTA @ TENT It was already very close to the deadline, but we couldn’t come up with any good ideas at all so that we decided to go to café together near our office to do a brainstorming.

SEICHIRO @ FUJITA Oh, really!

HARUTA @ TENT Actually, one of the most difficult tasks was to produce the product by only using metal. We visited your factory on the very beginning and we already knew your factory is really good at metal processing, but resin molding is out of your specialties.

AOKI @ TENT A frying pan with detachable handle isn’t very new to the market. There are many products like that, but most of them accomplish a locking mechanism of detachable handle by using plastic resin.

AOKI @ TENT First, we decided to figure out how we can accomplish the locking mechanism of detachable handle by only using metal.

SEICHIRO @ FUJITA Oh! So many ideas you guys came up with!

HARUTA @ TENT Within the constraint of only using metal, it is easy to come up with ideas of using a tong or fixing screw to hold the frying pan. But something told us those ideas are not right for this time.

AOKI @ TENT If we use the tong to hold the frying pan, we have to hold it pretty hard to carry the it safely. Using the fixing screw to attach the handle is not ideal at all for daily use. We put a lot of thought into this locking mechanism to be able to come up with the easy handling detachable handle without using plastic resin.

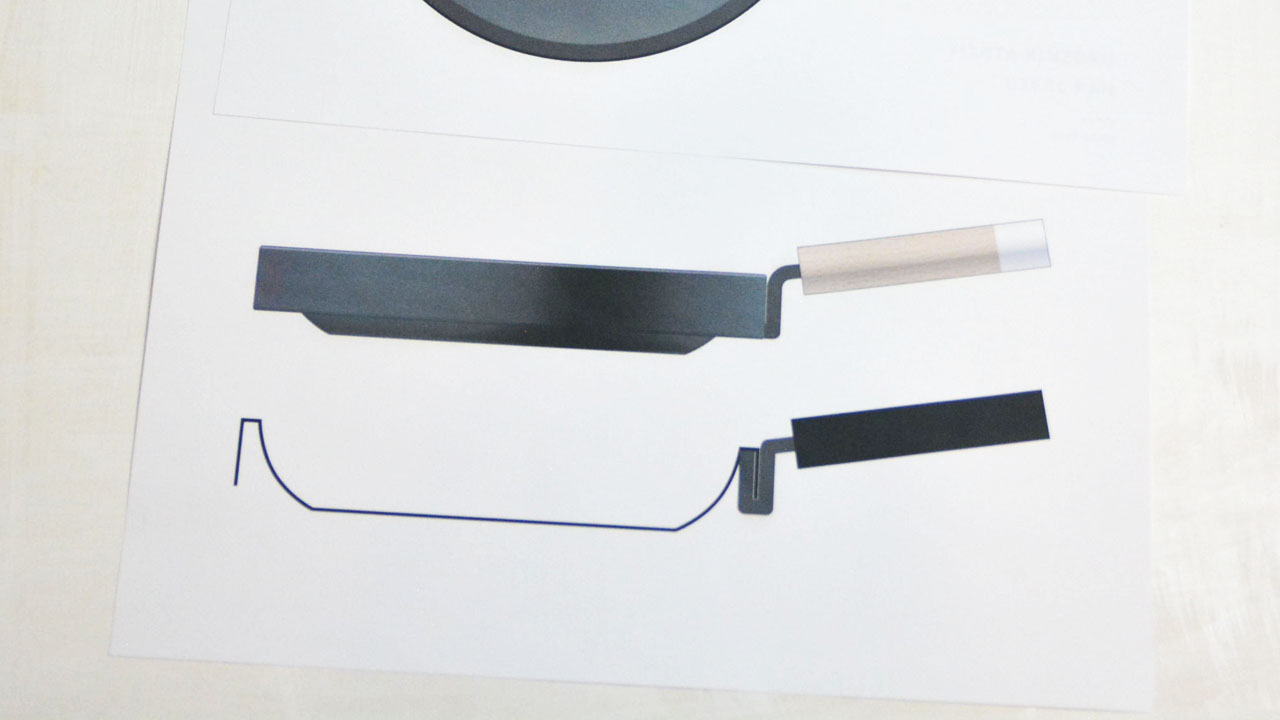

AOKI @ TENT While we were having deep thoughts on the structure of the handle, I suddenly hit upon a new idea. The idea was to add some sort of structure to the frying pan instead of only focusing on the structure of the handle.

HARUTA @ TENT We thought that the structure of the detachable handle could become very simple by adding a little contrivance to the edge of the frying pan.

SEICHIRO @ FUJITA I see, but the design is still quite different from the final version.

AOKI @ TENT By making a wide wall to the edge of the frying pan, the handle can be easily attached by hooking on it. It is not only easy to attach but it also provides the stability.

HARUTA @ TENT We were looking at this sketch for a while, and then we realized; “oh, doesn’t this look like a plate?”

AOKI @ TENT This is when we became convinced that producing the ”plate-like” frying pan can be realized. From then, we just needed to re-design it to make it look more like the plate.

HARUTA @ TENT Now, we are getting close to the first sketch we saw here.

SEICHIRO @ FUJITA Now I know. I saw this sketch in the very first meeting without knowing this story. That’s why I was so surprised that you managed to come up with such a great idea at once.

AOKI @ TENT But this was the beginning of long journey…

SEICHIRO @ FUJITA Indeed. It actually was the long journey…

AOKI @ TENT Yes, we already had an idea of the sliding handle, but structuring easy-to-use simple sliding mechanism was incredibly tough.

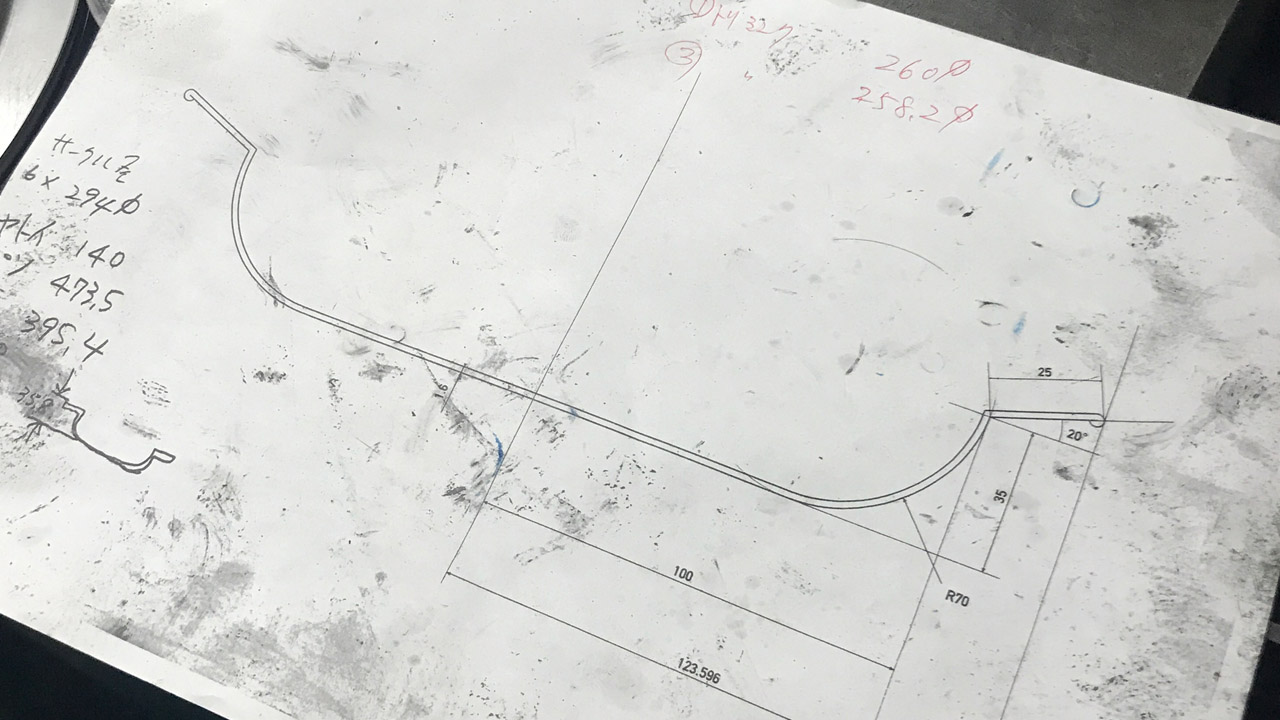

HARUTA @ TENT Besides the structure, thick iron plate gives more load on the handle than you imagine.

AOKI @ TENT Our aim is to produce “ordinary day-to-day use” product, so that we did not want to produce anything fancy and pricey. We put so much effort on finding the best possible simple structure and tested so many structure models.

SEICHIRO @ FUJITA There were so many issues which we cannot find out unless we actually produce and test it.

AOKI @ TENT Stabilizing metal processing accuracy was so much harder than we expected. It works well with mockup made by 3D printer, but it became wobbly with metal.

HARUTA @ TENT The key factor here was to keep the structure simple at the same time of making it have adequate variation tolerance for metal processing.

AOKI @ TENT We had continued to draw hundreds of sketches and made prototypes day after day. At last, we managed to produce a practical prototype. At that time, I couldn’t wait to try this prototype at home.

SEICHIRO @ FUJITA Oh, I remember what happened after this. You experienced a distressing incident. “The Omurice Incidnet” (Omurice is Japanese dish blending omelets and fried rice.)

HARUTA @ TENT That’s it! I had been using the prototype for several weeks without any issue. On one weekend, I cooked omurice for my kids. And the incident suddenly happened while I was carrying it.

HARUTA @ TENT The inner metal parts flabbily got bent.

AOKI @ TENT Luckily, the frying pan didn’t come off from the handle and no one got injured. This incident made us realized again that only calculating load point and running load test isn’t good enough. This time, the load applied from unexpected angle, and inner parts couldn’t bear the load.

SEICHIRO @ FUJITA And we went back to square one.

AOKI @ TENT Yeah, I was going to go crazy for a while. I had been thinking about this structure even in my dream. But I eventually came up with new solution.

SEICHIRO @ FUJITA We finally found the way to complete the new structure which we aimed for. But we had to take a process of trial and error again to reduce variation of processing such as by adjusting welding points. we just had to keep repeating the tests and adjustments.

HARUTA @ TENT Eventually, in our office we were literally surrounded by metal parts.

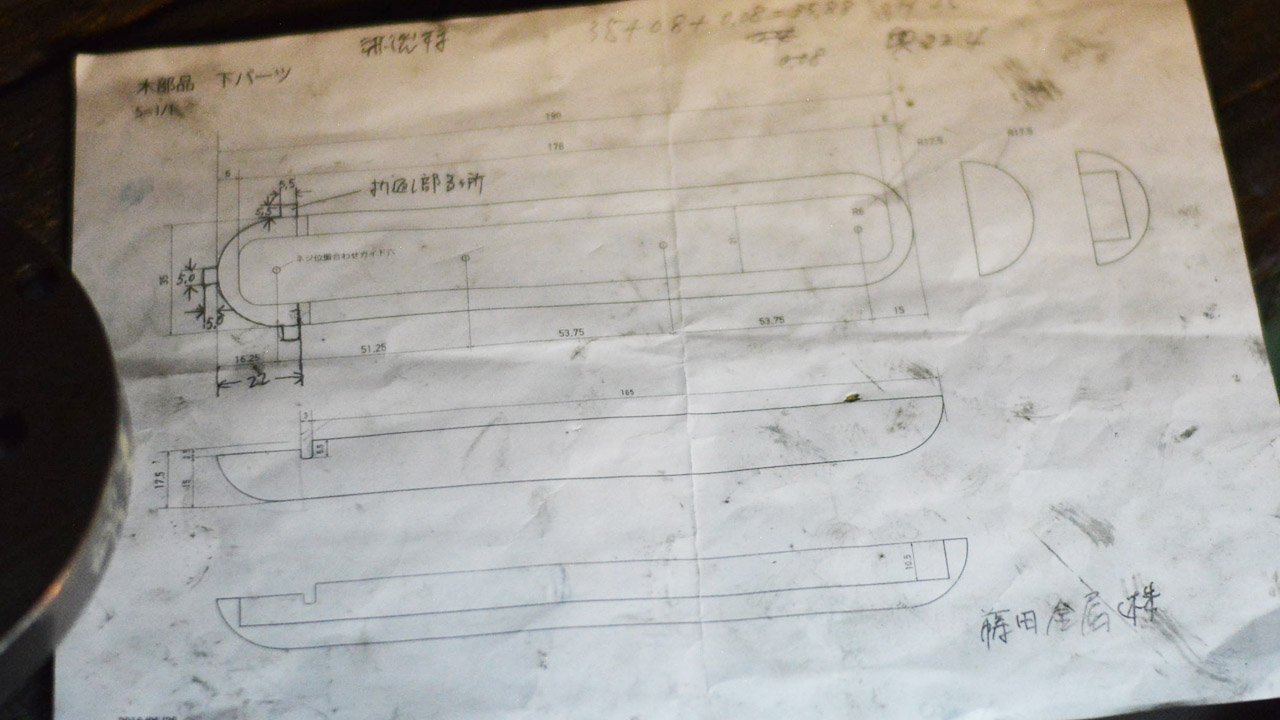

SEICHIRO @ FUJITA We ended up spending several months for making a lot of minor modification such as adjust internal structure of wood parts by 0.5mm, adjusting thickness of metal parts and position of screw by few millimeters, change welding method and so on.

AOKI @ TENT But look at this smooth sliding structure! This is our fruit of labor!

AOKI @ TENT To be able to produce the simple but sophisticated product, countless verifications and efforts are required. This project was one of the longest projects I ever had in my life. How about you Seichiro?

SEICHIRO @ FUJITA I haven’t really had an opportunity to make this kind of challenges in my life. So, I really was over my head. To be honest, I thought about giving up a few times.

HARUTA @ TENT Anyhow, I am truly relived to see the frying pan “JIU” in the market now.

AOKI @ TENT The structure is really simple, and it is very comfortable to use. You would probably think “where and how did you spend so much time on this?” Actually, you don’t have to think or remember about this story of “Endless Trials”. We want everyone to just enjoy using this product every day.

SEICHIRO @ FUJITA I don’t think I can never forget this experience…

HARUTA @ TENT Let’s keep using this frying pan until we forget what we went through during the production.

AOKI @ TENT Yeah, you are quite right.

SEICHIRO @ FUJITA The iron frying pan can last a lifetime. The more you use, the more mature it becomes.

Combine “COOKING” & “EATING” into one

Produced by a small-town factory in JAPAN.

The Frying Pan “JIU”

Please try it one! You will surely like it.

Thank you very much for reading our story of the planning and the production through to the end.

Should you have any comments and queries on this story, or any requests for interviews, please feel free to contact us at any time.

Email: info[at]tent1000.com

※please replace “[at]” with “at sign”

Contact Person: AOKI / TENT

FRYING PAN JIU & HANDLE SET

Size S / Beech Wood

¥ 6,600-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 21.5 x 3.6cm / 8.5 x 1.4inch

JIU: Inner Size (I.D x D x B.D) 16 x 3 x 12cm / 6.3 x 1.2 x 4.7inch

JIU Weight: 560g / 1.23lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & HANDLE SET

Size S / Walnut Wood

¥ 7,700-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 21.5 x 3.6cm / 8.5 x 1.4inch

JIU: Inner Size (I.D x D x B.D) 16 x 3 x 12cm / 6.3 x 1.2 x 4.7inch

JIU Weight: 560g / 1.23lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & HANDLE SET

Size M / Beech Wood

¥ 7,700-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 25.5 x 4.2cm / 10 x 1.7inch

JIU: Inner Size (I.D x D x B.D) 20 x 3.6 x 14.5cm / 7.9 x 1.4 x 5.7inch

JIU Weight: 780g / 1.7lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & HANDLE SET

Size M / Beech Wood

¥ 8,800-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 25.5 x 4.2cm / 10 x 1.7inch

JIU: Inner Size (I.D x D x B.D) 20 x 3.6 x 14.5cm / 7.9 x 1.4 x 5.7inch

JIU Weight: 780g / 1.7lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & HANDLE SET

Size L / Beech Wood

¥ 8,800-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 30 x 4.5cm / 11.8 x 1.8inch

JIU: Inner Size (I.D x D x B.D) 24 x 4 x 18cm / 9.4 x 1.6 x 7.1inch

JIU Weight: 1040g / 2.29lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & HANDLE SET

Size L / Walnut Wood

¥ 9,900-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 30 x 4.5cm / 11.8 x 1.8inch

JIU: Inner Size (I.D x D x B.D) 24 x 4 x 18cm / 9.4 x 1.6 x 7.1inch

JIU Weight: 1040g / 2.29lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & Handle Set,

M POT / Beech Wood

¥ 8,800-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 26 x 7cm / 10.2 x 2.8inch

JIU: Inner Size (I.D x D x B.D) 20 x 8 x 13cm / 7.9 x 3.1 x 5.1inch

JIU Weight: 875g / 1.93lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)

FRYING PAN JIU & Handle Set,

M POT / Walnut Wood

¥ 9,900-

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

JIU Outer Size (O.D x H): 26 x 7cm / 10.2 x 2.8inch

JIU: Inner Size (I.D x D x B.D) 20 x 8 x 13cm / 7.9 x 3.1 x 5.1inch

JIU Weight: 875g / 1.93lbs

HANDLE Size (L x H): 19 x 3.5cm / 7.5 x 1.4inch

HANDLE Weight: 195g / 0.43lbs (subjected to change)