Nowadays, working or studying from home became more common.

We are spending more time in our house, and every so often we seek for refreshing moments in the limited space of the house.

Since having greenery in our sight often helps us to have the moment to relax, we have realized that we want to feel more connected to nature than ever in our homelife.

Having those thoughts, designers and experienced craftsmen worked closely together and created the new masterpiece plant pot, “HACHI”.

But creating new products from scratch never be easy.

FUJITA METAL has been manufacturing frying pans as their flagship product since their establishment. It’s a new and unknow experience for them to manufacture plant pots.

Now, I would like to talk about twists and turns of the plant pot “HACHI”’s production story.

1.Not just the appearance but with the rational structure design.

FUJITA METAL MFG co., ltd

Seichiro Fujita (hereafter FUJITA) :

Why did you want to produce plant pots in the first place?

Design Team TENT

Ryosaku Aoki (hereafter AOKI) :

We always have been discussing what we want to create next, and since several years ago, HARUTA-san had been saying…

Design Team TENT

Masayuki Haruta (hereafter HARUTA) :

Yeah, I am growing plants at home, and I had always been thinking to create a product which is related to plants.

But there are thousands of amazing plant related products in the market already.

There is no point producing something similar to existing products. So, I didn’t take it further.

From the left: HARUTA, FUJITA, and AOKI.

FUJITA:

And how come you decided to create one afterwards?

HARUTA:

One day, you said that you want to try producing not frying pans but something new and different. That triggered me to think about creating plant related products again.

FUJITA:

Ah, yes. I said that. It was back in end of 2019.

HARUTA:

I think so. Anyway, I was looking at plant pots at home for a while. Then, I thought that it seems little unreasonable to categorize plant pots as home decor.

AOKI:

Unreasonable?

HARUTA:

Yes, plant pots are generally designed for outside use. There is a hole on the bottom for allowing excess water to drain.

Then, you need to use saucers to catch excess water if you use it inside the house.

AOKI:

There are some plant pots without drainage holes, but it may cause root rot, isn’t it? So, it‘s better to use the one with drainage holes

HARUTA:

That’s right. You need to use saucers if you want to use them indoor. But plant pots and saucers are not “well together”.

FUJITA:

What do you mean exactly?

HARUTA:

It is obvious that saucers are needed for indoor use, but they are not designed well for it.

FUJITA:

Hmmm… I see.

HARUTA:

Various materials are used to manufacture plant pots, and wide range of designs and colors are available. From the product appearance point of view, it seems that there is no more room for new products to get in.

Having said that, however, there are not many plant pots that are well thought out from the industrial point of view.

FUJITA:

Uh-huh.

HARUTA:

This is how I started to think about creating plant pots with not only the appearance but with the rational structure design.

AOKI:

And spring of 2020 arrived.

2.“Working from home” & “the cup”.

HARUTA:

COVID-19 pandemic happened, and our lifestyle got affected significantly. It has totally changed.

TENT (AOKI & HARUTA) decided to work remotely. I literally stayed at home from morning till night.

I spent my time at home more than ever. So, I wanted to make my home environment more comfortable by getting more greenery in the house.

So, I started to spend more hours to think up some ideas for the new plant pot. I used 3D printer and produced prototypes again and again, and I ended up surrounded by them.

AOKI:

And you finally arrived at that structure.

HARUTA:

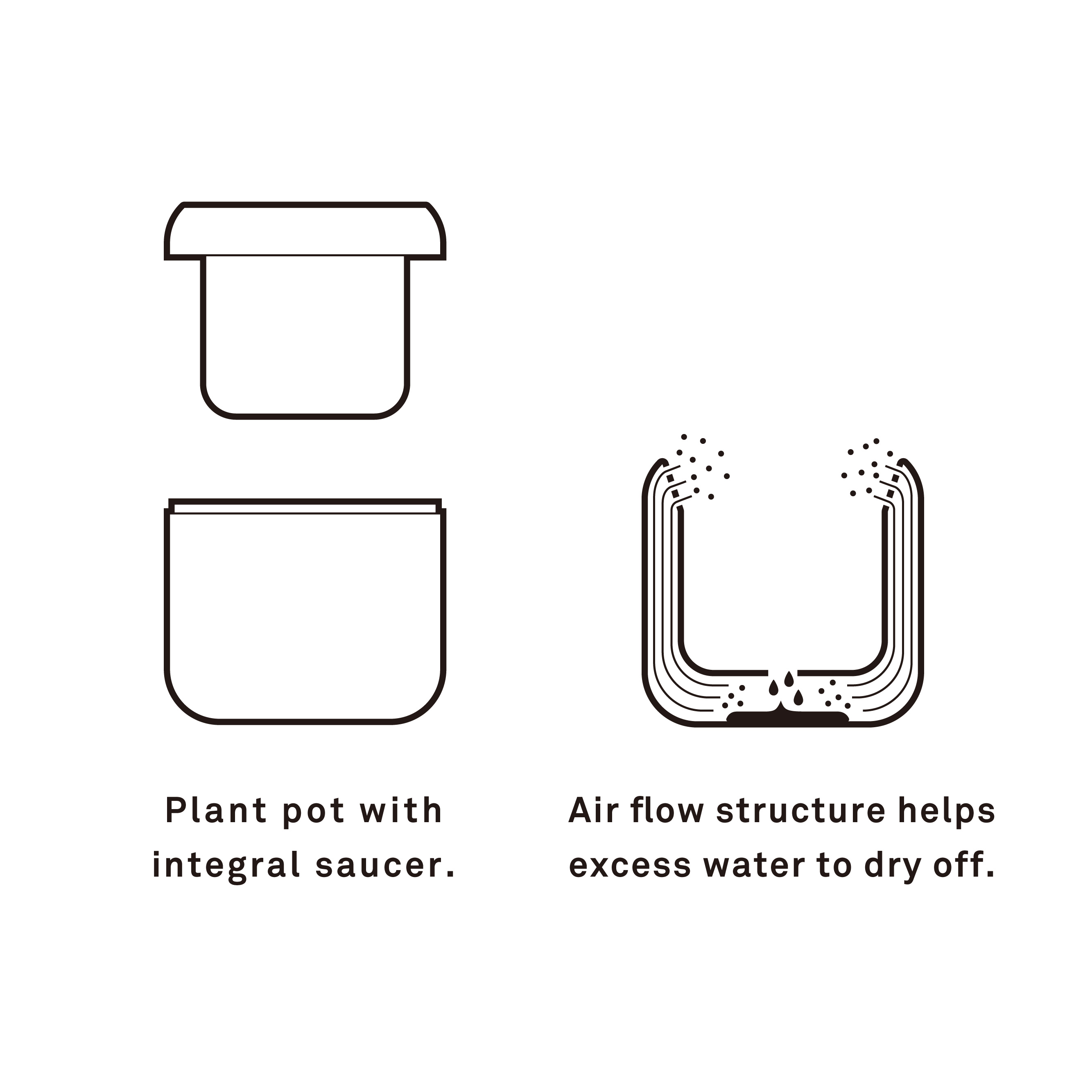

Yes! The double-wall structure.

AOKI:

Could you please explain more about it?

HARUTA:

A drainage hole is essential for keeping plants healthy. But from home décor point of view, seeing soil and excess water in a saucer is not visually pleasant.

Then, I came up with the idea of adapting the double-wall structure, which is often used for cups to increase heat retention.

FUJITA:

Ah-ha, I got your point.

AOKI:

What is it?

FUJITA:

With existing products, you have to use your both hands to carry a plant pot and saucer. It is not very user friendly.

But with the double wall structure, you only need one hand to carry. On top of that, it is visually smart. It makes perfect sense!

HARUTA:

After I decided the structure, I thought that it can be manufactured by using metal spinning process. So, I decided to talk to you, FUJITA-san.

Major materials for plant pots are plastic, pottery, or glass. Using metal for plant pots is not very common, and make good use of metal’s characteristics would be new and interesting.

FUJITA:

You are quite right. I don’t often see metal plant pots.

3.Deriving the shape from the theme

AOKI:

The shape of Plant Pot “HACHI” doesn’t look like typical plant pots. Could you explain why?

HARUTA:

As I had been working remotely for a long time, the image I strongly had in my mind was the plant pot which naturally fit into my workspace.

So, I was seeking for the design which naturally sit next to my laptop.

I thought it would be better to imagine precision electrical device like a portable Bluetooth speaker.

FUJITA:

That’s interesting.

HARUTA:

Conventional products are designed to be used outside. So, soil inside a plant pot or excess water in a saucer stands out. These things catch my eyes.

Ideally, I only want to see plants. So, I designed the plant pot which can bring your focus on plant itself and hide all other visually unnecessary things as much as possible.

HARUTA:

I got one more thing I would like to talk about. It is not about the design.

AOKI:

Please carry on.

HARUTA:

In the past, I was astonished by the product called ABITAX. The top and bottom body is made of aluminum, and the plastic sliding cap combines these two parts.

AOKI:

Is this the one you are talking about?

HARUTA:

Yes, this is it. It deserves respect as this is one of the perfect answers for minimal design while making the best use of the material. If I can create such product, one of my dreams will come true again.

FUJITA:

I didn’t know there are such deep thoughts and feelings behind the design.

AOKI:

You went through many trials and errors to make his dream come true, didn’t you FUJITA-san?

4.Processing methods are never straightforward.

FUJITA:

Yes, it was a long way to go. The metal spinning process is basically mixture of stretching and forming the metal sheet into the shape. In the case of mass-manufacturing, manufacturing two parts with high degree of precision and making them fit perfectly is really challenging.

AOKI:

It sounds tough.

FUJITA:

To begin with, producing this mushroom-like shape is more difficult than you imagine.

HARUTA:

How many processes did you have to go through for mass-production?

FUJITA:

Cutting metal sheet, pressing, spinning, forming, then folding back…

And punching a hole in the inner pot.

HARUTA:

You are right. 1 large hole for drainage and 33 tiny holes for ventilations are needed.

FUJITA:

The shape of pots is precisely formed with much effort first, and the process of punching holes comes after that.

The critical issue we had was that the shape deforms when punching holes. I really struggled on this part.

HARUTA:

We also had to figure out adequate quantity of holes for ventilation. It is important as it directly affects plant’s environment. Those holes also need to be hard to spot for visual reason. We made so many prototypes again on this stage.

AOKI:

Every prototype we made was a failure as the shape of pot or holes deformed. At that time, I started to think it might not be possible to mass-produce this plant pot…

FUJITA:

To solve this problem, we decided to make a mold only for punching holes. This could have been a critical issue if we couldn’t manufacture it in house.

My dad was saying that if we place an order to the mold manufacturer, it could cost us over US$ 50k.

HARUTA:

You got to be kidding…

AOKI:

So far, we talked about forming processes. We still have finishing processes.

FUJITA:

You requested the fine emboss processing, matte surface, and black alumite treatment. (Anodic Oxidation Coating)

HARUTA:

Indeed, these are popular finishes for household electric appliances. What I wanted was smooth and matte surface.

FUJITA:

I sometimes use the alumite treatment when I manufacture frying pans and cups. But I had no experience on such delicate emboss processing.

AOKI:

I remember you said it’s fairly easy to do it if it’s not this delicate emboss pattern.

FUJITA:

Yes, our subcontract factories couldn’t do it. So, I asked you guys to help me out finding a new subcontract factory.

HARUTA:

We made contact to so many factories, and we end up finding one just nearby your factory.

FUJITA:

I know, it’s hard to see what is under your nose.

It’s really nearby! I actually drive myself to that factory for delivery and pick up.

AOKI:

I’m so impressed about Yao-city, Osaka. You can find everything you need for manufacturing!

5.In 8 years’ time.

HARUTA:

How did you feel when we said we want to produce plant pots?

AOKI:

Did you not feel awkward? We were asking the frying pan factory to produce plant pots.

FUJITA:

Surprisingly, I never thought that. You know what I noticed later on?

AOKI:

What is it?

FUJITA:

One day, I had an opportunity to look back at old photos of our factory and products. I found one photo which was taken 8 years ago, year 2012.

HARUTA:

Oh my! you are using tea pots as plant pots.

AOKI:

You were thinking about manufacturing plant pots from 8 years ago!

FUJITA:

Back in 2012, we were losing our bearings, and we were looking for new possibilities. When we produced new products for mass merchandiser market, we were forced to lower the price significantly. When we produced a new unique product, it got copied by foreign companies and sold in lower price.

So, we were probably trying to find out the way to use existing products in the different category and put flowers and greeneries in the tea pot for trial.

HARUTA:

You know what? Some tea pots have a tea strainer inside. It is same as the double wall structure of Plant Pot “HACHI”!!

FUJITA:

This “tea pot plant pot” was placed at out factory’s entrance for a while, but we never actually tried to sell it. I never imagined about manufacturing and selling plant pots after 8 years of time.

AOKI:

I see. You already thought about selling plant pots before. That’s why you never felt awkward when you heard our plan.

FUJITA:

Yes, that’s probably why.

AOKI:

To conclude, are there any messages you would like to send to readers?

HARUTA:

As we are spending more time at home due to COVID-19 pandemic, I think there are many more people who started to think about growing plants at home, just like me.

But there are many things you have to think before you start growing plants at home. What sort of plant is more suitable for growing indoor? What do I need for growing them?

AOKI:

I know! My wife is growing plants at home, but if it were me, I wouldn’t know where to start.

HARUTA:

I think I made a new option of “buying the plant pot before plants”. It is a new way to start growing plants especially for those who don’t have any experience.

FUJITA:

That’s indeed new.

AOKI:

It’s reverse thinking. Purchasing a plant pot first and look for a plant which is suitable for it. It‘s interesting.

Is there anything you would like to say, FUJITA-san?

FUJITA:

This plant pot naturally fit into any atmosphere. From bedside tables to dining tables, and from work desks to balcony, you can take this plant pot anywhere you like by just one hand.

It‘s really handy for watering too.

HARUTA:

You can fill up water in the outer pot and soak the inner pot for a while too.

AOKI:

We should be able to discover many other ways as we use more!

Well, Thanks so much for your time, everyone.

FUJITA & HARUTA:

Thank you too!

Whether you are a plant lover or beginner, Plant Pot “HACHI” will bring nature closer to you and increase quality of your homelife.

We hope you will enjoy the great experience of Plant Pot “HACHI”

Should you have any comments and queries on this story, or any requests for interviews, please feel free to contact us at any time.

Email: info[at]tent1000.com

※please replace “[at]” with “at sign”

Contact Person: AOKI / TENT

The Plant Pot “HACHI”

2 ½ ” inner diameter (6cm)

¥3,850

Product Size and Weight (Approximate Size in cm / inch / g / lbs)

Inner Pot (I.D x H): 6 x 6.4 cm / 2.36 x 2.51 inch

Outer Pot (O.D x H) 8.4 x 8 cm / 3.30 x 3.15 inch

Weight: 75 g / 0.16 lbs

【CAUTION】

This product is NOT for outdoor use. Aluminum has a high thermal conductivity and extreme high/low temperature may cause temporary or permanent damage to your plant.

The Plant Pot “HACHI”

3” inner diameter (6cm)

¥4,950

Product Size and Weight (Approximate Size in cm / inch /g / lbs)

Inner Pot (I.D x H): 9 x 8.9 cm / 3.54 x 3.50 inch

Outer Pot (O.D x H) 11.4 x 10.4 cm / 4.48 x 4.09 inch

Weight: 142 g / 0.31 lbs

【CAUTION】

This product is NOT for outdoor use. Aluminum has a high thermal conductivity and extreme high/low temperature may cause temporary or permanent damage to your plant.